Komarks > Print Capabilities + Certification

Packaging & Labelling

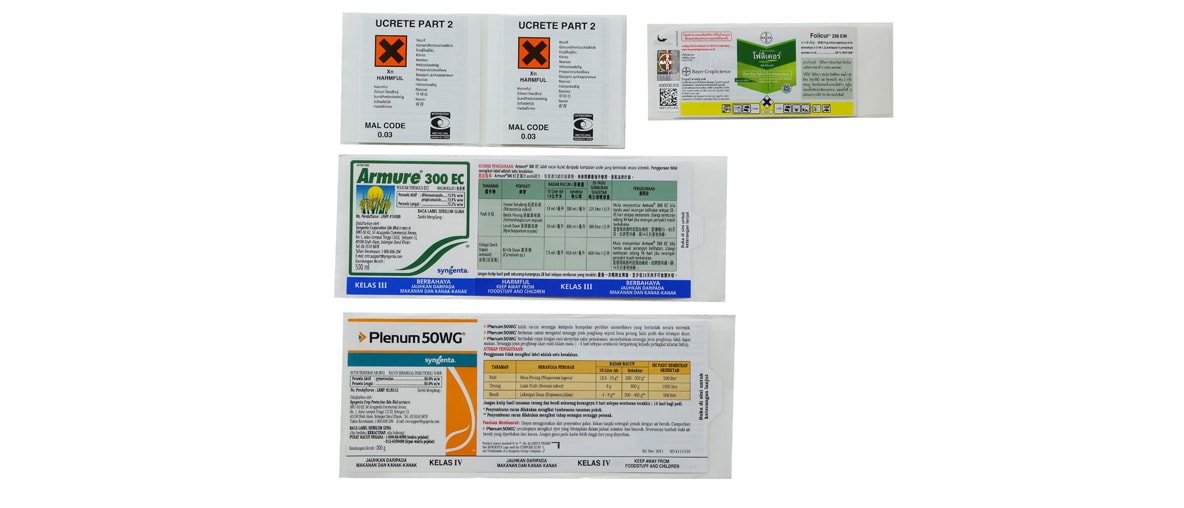

- Chemicals & Agrochemicals

- Food & Beverage

- Home & Personal Care

- Industrial & Lubricants Oil

- Pharmaceutical

- Promotion

- Security Solution

- Digital Solution

- Automatic Labelling Machine

- Flexible Packaging Solution

BOPP Roll-On Labels – We make use of shrinkable BOPP film to provide a shrink capability which is ideal for the decoration of contoured bottles or cans. The BOPP film labels are wrapped around the container and sealed with hot-melt adhesive. We print on clear or white film ranging from 12 microns to 100 microns.

Shrink Sleeve Labels

Shrink sleeve labels are ideal for your complex containers, safety seals and promotional packaging needs. Plastic sleeves are measured precisely and then heat-shrunk for a wrap-around fit for any plastic, glass or metal container. They can be used on:

- Food and beverages

- Personal care

- Pharmaceutical products and

- Chemical and agrochemical

- Household products

Being a shrink sleeve supplier, our shrink sleeve label can be made from both commonly used in the market – Polyvinyl chloride (PVC) and Polyethylene Terephthalate Glycol-modified (PETG).

Printing of Flexible Packaging

Flexibles or film based labels have become a popular choice of labelling today due to many advantages offered compare to that of the traditional paper label, silk screen, lithographic printing, and etc.

Due to the increased demand in flexibles labels, Komark has ventured into producing flexibles labels as a flexible packaging supplier to better serve its valuable customers. Therefore, a series of state of the art equipment have been installed specially for the production of film based labels.

We are capable of producing up to 10 colors printing design; 8 surface colors and 2 backside colors. The backside printing capability is indeed specially cater for promotional labels where front and back of the label is fully utilize to maximize its effectiveness. What’s more, we are also capable of producing laminated labels to further enhance the finishing and print protection of the label. All these allow us to produce highly demanding label design which is a requirement for today’s highly competitive market environment.

With all the capabilities mentioned above, equally important to us is the environmental issue where it is no compromise along the production process. The printing technology engaged is flexography printing technology which is environmental friendly where environmental friendly inks are used. This is not only critical to the environment, but it is equally important to human’s health.

Today, we are capable of producing heat shrinkable PETG or Polyvinyl Chloride (PVC) sleeve and laminated roll-fed Bi-Oriented Polypropylene (BOPP) label as well as other range of flexibles packaging.

ROLL-FED BI-ORIENTED POLYPROPYLENE (BOPP) LABEL

Characteristics:

- Roll-fed labelling.

- Single layer or laminated film structure.

- Suitable for round and square bottles.

- 360° wraparound.

- High gloss.

- Environmental friendly.

- Excellent moist barrier.

- Good tear resistance.

BOPP roll-fed label is becoming popular for metal can and round PET and glass containers. It allows high speed labelling for large volume usage. It is a great substitute labelling option for conventional lithographic printed cans for beverage products where wide ranges of variants are offered.

Roll-fed label can be laminated with two layers of BOPP films. With the new flexographic press featured with Central Impression Drum, very thin film can be printed to keep cost at minimal level. Laminated labels will protect prints from scuffing off and better labelling efficiency.

Roll-fed labels are closely related with large volume usage due to investment involved for labelling machine. With its significant volume consume annually, the investment on labelling machines became insignificant due to cost savings on roll-fed labels.

HEAT SHRINKABLE PETG or POLYVINYL CHLORIDE (PVC) SLEEVE